Raws li kev lag luam hloov zuj zus, qhov kev thov rau cov cuab yeej txiav ua haujlwm siab txuas ntxiv mus, nrog rau cov hniav tungsten carbide ua tus thawj coj. Hauv cov blog no, peb tshawb nrhiav cov qauv hniav tungsten carbide uas tsim lub neej yav tom ntej ntawm cov hniav lag luam, tshuaj xyuas cov tsav tsheb tseem ceeb ntawm kev ua lag luam, thiab kwv yees cov cib fim loj hlob rau xyoo 2025 thiab tom qab ntawd. Txij li aerospace mus rau automotive, qhov xav tau kev ua kom raug thiab kev ruaj khov yog tsav tsheb tsim kho tshiab hauv qhov kev lag luam no.

Kev Xav Tau Ua Lag Luam Loj Hlob: Kev Lag Luam Aerospace thiab Automotive

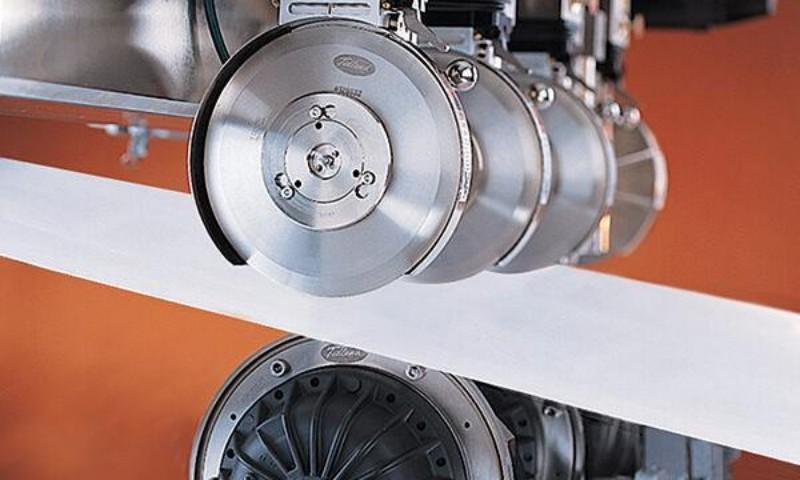

Lubcov cuab yeej txiav kev lag luam thoob ntiaj tebkev ua lag luam tab tom loj hlob zoo, vim muaj kev nthuav dav ntawm kev lag luam xws li aerospace thiab automotive:

Kev Ua Haujlwm Dav Hlau:Cov kev lag luam aerospace xav tau cov cuab yeej txiav precision rau kev siv cov khoom siv sib dua, muaj zog siab xws li titanium thiab composites. Cov hniav tungsten carbide, uas paub txog lawv qhov nyuaj thiab tiv taus kev hnav, yog qhov zoo tagnrho rau cov ntawv thov no. Nrog rau kev tsim khoom thoob ntiaj teb aerospace xav tias yuav nce 5% txhua xyoo, qhov kev thov rau cov hniav ruaj khov yuav nce ntxiv.

Tsheb:Kev hloov mus rau cov tsheb fais fab (EVs) thiab cov khoom siv sib dua (piv txwv li, txhuas, carbon fiber) ua rau muaj kev xav tau cov kev daws teeb meem siab heev. Cov hniav tungsten carbide yog qhov tseem ceeb rau kev txiav ceev ceev, siab-precision hauv kev tsim roj teeb EV thiab kev tsim chassis, nrog rau kev lag luam tsheb kwv yees tias yuav loj hlob 4% hauv xyoo 2025.

Cov kev lag luam no tab tom tsav cov qauv ntawm cov hniav tungsten carbide, vim tias cov chaw tsim khoom nrhiav cov cuab yeej uas xa tau lub neej ntev dua, ua haujlwm tau zoo dua, thiab siv nyiaj tau zoo.

Cov Ntsiab Lus Kev Loj Hlob Uas Kwv Yees Rau Tungsten Carbide Blades

Kev lag luam ntawm cov hniav tungsten carbide tau npaj rau kev nthuav dav, nrog rau ntau yam tseem ceeb uas ua rau kev loj hlob:

- Cov Ntaub Ntawv Kev Loj Hlob ntawm Kev Lag Luam:Cov ntawv ceeb toom kev lag luam kwv yees tias kev lag luam thoob ntiaj teb ntawm cov hniav tungsten carbide yuav loj hlob 6.5% hauv xyoo 2025, vim muaj kev xav tau cov cuab yeej tiv taus kev hnav hauv kev ua haujlwm raug. Kev loj hlob no yog los ntawm kev siv cov tshuab txiav tsis siv neeg thiab kev txiav ceev ceev.

- Kev Txhim Kho Txog Kev Siv Tshuab:Cov kev tsim kho tshiab hauv cov txheej txheem hniav (piv txwv li, cov pa roj carbon zoo li pob zeb diamond, TiN) ua rau muaj kev ruaj khov thiab txo qhov kev sib txhuam, ua rau cov hniav tungsten carbide sib tw ntau dua. Cov kev nce qib no sib haum nrog yav tom ntej ntawm cov hniav lag luam, qhov twg kev ua haujlwm zoo thiab lub neej ntev yog qhov tseem ceeb.

- Cov Lag Luam Tshiab:Kev lag luam sai sai hauv Asia-Pacific thiab Latin America tab tom tsim cov cib fim tshiab. Piv txwv li, cov khoom tsim khoom hauv Suav teb yuav loj hlob 7% hauv xyoo 2025, ua rau muaj kev xav tau cov cuab yeej txiav zoo xws li cov hniav tungsten carbide.

Cov qauv no qhia txog lub peev xwm ua lag luam muaj zog rau cov hniav tungsten carbide, tshwj xeeb tshaj yog nyob rau hauv cov kev lag luam muaj kev thov siab.

Kev Tsim Khoom Siv Tau Ntev: Ib Lub Ncauj Lus Kub hauv Kev Tsim Kho Tshiab ntawm Cov Hniav

Kev ruaj khov yog hloov kho lub neej yav tom ntej ntawm cov hniav riam hauv kev lag luam, thiab cov hniav riam tungsten carbide yog cov nyob rau pem hauv ntej ntawm qhov kev hloov pauv no:

- Cov Khoom Siv Zoo Rau Ib Puag Ncig: Tungsten carbide siv tau dua tshiab, ua raws li cov ntsiab cai ntawm kev lag luam ncig. Cov chaw tsim khoom tab tom tsom mus rau cov txheej txheem tsim khoom ruaj khov, xws li txo kev siv hluav taws xob thaum lub sijhawm tsim cov hniav.

- Siv Tau Ntev Dua: Qhov ruaj khov ntawm cov hniav tungsten carbide txo qhov zaus hloov pauv, txo cov khib nyiab thiab txo qhov cuam tshuam rau ib puag ncig. Qhov no ua raws li lub hom phiaj tsim khoom ruaj khov, vim tias kev lag luam tsom mus rau kev txo kev siv cov peev txheej.

- Kev Siv Hluav Taws Xob Zoo: Cov txheej txheem siab heev thiab cov qauv hniav zoo tshaj plaws ua rau kev txiav zoo dua, txo kev siv hluav taws xob hauv cov txheej txheem machining. Qhov no yog qhov tseem ceeb rau cov lag luam xws li aerospace, qhov twg cov nqi hluav taws xob tseem ceeb.

Los ntawm kev lees txais kev ruaj khov, cov hniav tungsten carbide tsis yog tsuas yog ua tau raws li kev xav tau ntawm kev ua lag luam xwb tab sis kuj nyiam cov neeg yuav khoom uas paub txog ib puag ncig, txhawb nqa lawv txoj kev loj hlob hauv xyoo 2025.

Vim li cas thiaj yuav tsum nqis peev rau hauv Tungsten Carbide Blades Tam Sim No?

Cov qauv ntawm cov hniav tungsten carbide qhia txog yav tom ntej ci ntsa iab rau cov cuab yeej txiav no. Nrog rau kev thov ntau ntxiv los ntawm kev lag luam aerospace thiab automotive, kev nce qib ntawm thev naus laus zis, thiab kev tsom mus rau kev tsim khoom ruaj khov, cov hniav tungsten carbide tau teeb tsa los ua tus thawj coj hauv kev lag luam. Cov ntaub ntawv kev lag luam los ntawm cov ntawv tshaj tawm kev tsim khoom txhawb nqa qhov kev xav no, kwv yees kev loj hlob ruaj khov hauv kev siv txiav precision.

Npaj txhij los ua tus thawj coj ntawm cov riam? Tiv tauj peb kom tau txais kev qhia ntawm cov kws tshaj lij txog kev xaiv cov hniav kom raug rau koj cov kev xav tau:

Email: lisa@hx-carbide.com

Lub Vas Sab:https://www.huaxincarbide.com

Xov tooj & WhatsApp: + 86-18109062158

Tau txais cov lus qhia tshwj xeeb los ua kom koj cov haujlwm txiav zoo dua thiab siv qhov kev thov uas nce ntxiv raucov hniav tungsten carbide.

Lub sijhawm tshaj tawm: Lub Ob Hlis-17-2025