Cov hniav carbide ua li cas?

Cov hniav carbide muaj nqis rau lawv qhov nyuaj tshwj xeeb, hnav tsis kam, thiab muaj peev xwm tswj tau qhov ntse ntev, ua rau lawv zoo tagnrho rau kev txiav cov ntaub ntawv tawv.

Cov hniav carbide feem ntau yog ua los ntawm kev siv cov txheej txheem uas cuam tshuam nrog kev sintering tungsten carbide hmoov rau hauv daim ntawv khov kho, ua raws li kev puab thiab ua kom tiav cov hniav. Nov yog cov lus qhia ib kauj ruam zuj zus ntawm yuav ua li cas cov hniav carbide feem ntau tsim tawm:

1. Kev Npaj Khoom Siv Raw

- Tungsten CarbideHmoovCov khoom siv tseem ceeb hauv cov hniav carbide yog tungsten carbide (WC), uas yog cov khoom sib xyaw ua ke ntawm tungsten thiab carbon. Cov hmoov ntawm tungsten carbide yog sib xyaw nrog cov hlau sib txuas, feem ntau yog cobalt (Co), los pab nrog cov txheej txheem sintering.

- Hmoov Sib Tov: Cov hmoov tungsten carbide thiab cobalt raug sib xyaw ua ke los ua ib qho sib tov sib xws. Cov sib tov raug tswj kom zoo kom ntseeg tau tias muaj cov khoom sib xyaw kom raug rau qhov tawv thiab tawv ntawm cov hniav xav tau.

2. Nias

- Kev ua pwm: Cov hmoov sib tov raug muab tso rau hauv pwm lossis tuag thiab nias rau hauv ib daim duab compact, uas yog cov qauv ntxhib ntawm cov hniav. Qhov no feem ntau ua tiav hauv qab siab hauv cov txheej txheem hu uaKev nias txias isostatic (CIP) or kev nias ib sab.

- Kev Ua DuabThaum nias, daim duab ntxhib ntawm cov hniav raug tsim, tab sis nws tseem tsis tau ntom lossis tawv tag. Lub tshuab nias pab kom cov hmoov sib tov ua ke rau hauv cov duab geometry uas xav tau, xws li cov duab ntawm cov cuab yeej txiav lossis cov hniav.

3. Kev Sintering

- Kev Sintering Kub SiabTom qab nias, cov hniav yuav raug sintering. Qhov no suav nrog kev ua kom sov lub puab tsaig hauv lub cub tawg ntawm qhov kub feem ntau ntawm1,400°C thiab 1,600°C(2552 ° F txog 2912 ° F), uas ua rau cov hmoov av sib xyaw ua ke thiab tsim cov khoom khov kho, ntom ntom.

- Kev Tshem Tawm Cov Ntawv TxuasThaum lub sijhawm sintering, cov cobalt binder kuj raug ua tiav. Nws pab cov tungsten carbide particles lo rau ib leeg, tab sis tom qab sintering, nws kuj pab muab qhov kawg hardness thiab toughness rau cov hniav.

- TxiasTom qab sintering, cov hniav maj mam txias hauv ib puag ncig tswj kom tsis txhob tawg lossis cuam tshuam.

4. Kev Sib Tsoo thiab Kev Ua Duab

- Kev sib tsooTom qab sintering, cov hniav carbide feem ntau ntxhib dhau lossis tsis sib xws, yog li nws raug sib tsoo kom raug qhov loj me siv cov log abrasive tshwj xeeb lossis cov tshuab sib tsoo. Cov kauj ruam no yog qhov tseem ceeb rau kev tsim cov ntug ntse thiab xyuas kom meej tias cov hniav ua tau raws li cov lus qhia xav tau.

- Kev Ua Duab thiab Kev Txheeb XyuasNyob ntawm seb daim ntawv thov siv li cas, cov hniav yuav raug hloov kho lossis ua kom zoo nkauj ntxiv. Qhov no yuav suav nrog kev sib tsoo cov ces kaum tshwj xeeb ntawm ntug txiav, siv cov tshuaj pleev xim, lossis kho kom zoo nkauj tag nrho cov hniav.

5. Kev Kho Mob Tiav

- Cov Txheej Txheem Nto (Xaiv Tau): Qee cov hniav carbide tau txais kev kho mob ntxiv, xws li cov txheej txheem ntawm cov ntaub ntawv xws li titanium nitride (TiN), los txhim kho qhov nyuaj, tiv taus kev hnav, thiab txo kev sib txhuam.

- Kev txhuam hniav: Yuav kom ua tau zoo dua, cov hniav yuav raug txhuam kom du thiab tiaj tus uas txo kev sib txhuam thiab txhim kho kev txiav zoo.

6. Kev Tswj Xyuas Zoo thiab Kev Ntsuas

- Kev Ntsuas Qhov Nyuaj: Qhov nyuaj ntawm cov hniav feem ntau raug sim kom ntseeg tau tias nws ua tau raws li cov lus qhia xav tau, nrog rau kev sim feem ntau suav nrog kev sim Rockwell lossis Vickers hardness.

- Kev Tshuaj Xyuas Qhov Ntev: Kev ua kom raug yog qhov tseem ceeb, yog li qhov ntev ntawm cov hniav raug kuaj xyuas kom ntseeg tau tias lawv ua tau raws li qhov kam rau siab.

- Kev Ntsuas Kev Ua HaujlwmRau cov ntawv thov tshwj xeeb, xws li kev txiav lossis kev txiav, cov hniav yuav raug kuaj xyuas hauv lub ntiaj teb tiag tiag kom paub tseeb tias nws ua haujlwm raws li tau npaj tseg.

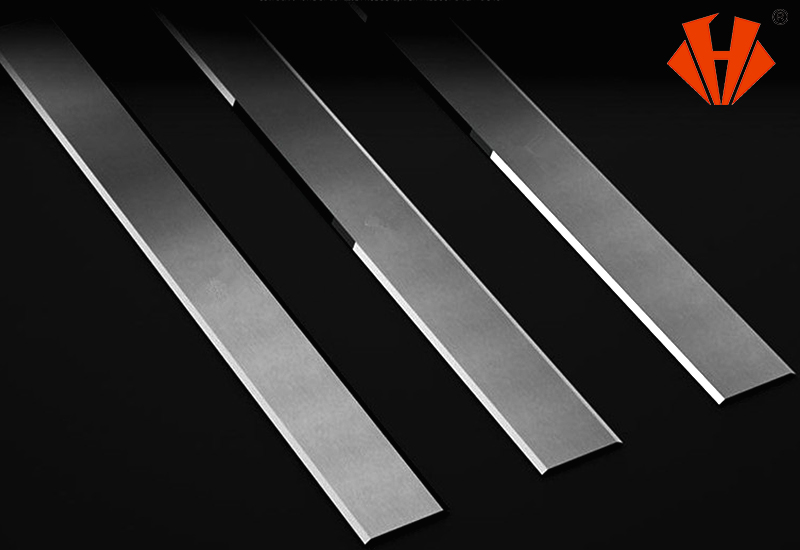

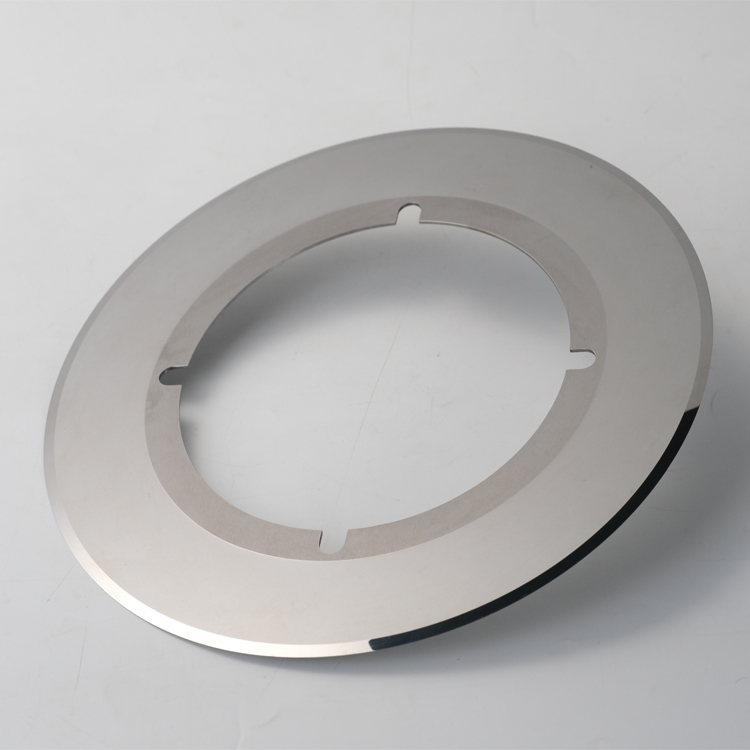

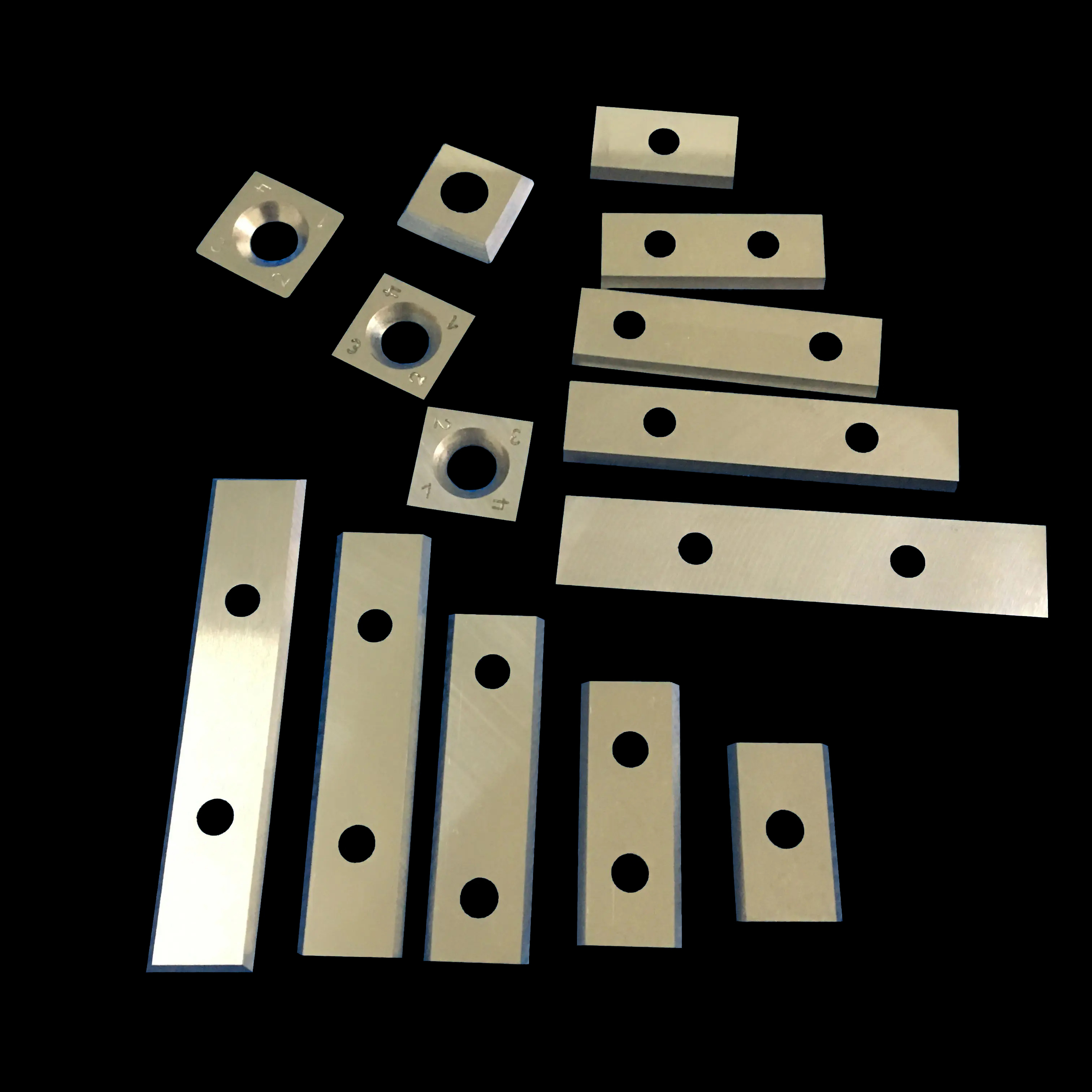

HUAXIN CEMENTED CARBIDE muab cov riam thiab cov hniav tungsten carbide zoo tshaj plaws rau peb cov neeg siv khoom los ntawm ntau yam lag luam thoob plaws ntiaj teb. Cov hniav tuaj yeem teeb tsa kom haum rau cov tshuab siv hauv txhua daim ntawv thov kev lag luam. Cov ntaub ntawv hniav, qhov ntev ntawm ntug thiab cov qauv, kev kho thiab cov txheej txheem tuaj yeem hloov kho rau kev siv nrog ntau yam khoom siv kev lag luam.

Thaum cov hniav tau dhau tag nrho cov kev kuaj xyuas zoo, lawv npaj txhij rau kev siv rau hauv ntau yam kev siv hauv kev lag luam, xws li hauv kev ua hlau, ntim khoom, lossis lwm yam kev txiav uas qhov kev tiv taus hnav siab thiab ntse yog qhov tseem ceeb.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-25-2024