Yuav kom tiv thaiv cov riam txiav ntawm lub tshuab ua ntawv luam yeeb, nws yog ib qho tseem ceeb uas yuav tsum siv ntau yam kev coj ua txij nkawm thiab cov lus qhia ua haujlwm kom ntseeg tau tias lawv siv tau ntev thiab ua haujlwm tau zoo tshaj plaws. Nov yog qee cov tswv yim zoo:

1. Kev Txij Nkawm thiab Kev Tshuaj Xyuas Tsis Tu Ncua

- Kev Tshuaj Xyuas Tsis Tu Ncua:Tshawb xyuas cov riam tsis tu ncua seb puas muaj cov cim qhia tias puas lawm, tawg, lossis tsis ci. Kev kuaj pom thaum ntxov ntawm kev puas tsuaj tuaj yeem tiv thaiv kev puas tsuaj ntxiv thiab txo qhov kev pheej hmoo ntawm kev ua tsis tiav ntawm cov hniav.

- Teem sijhawm kom ntse:Tsim ib daim ntawv teem sijhawm rau kev ua kom cov riam ntse raws li kev siv thiab cov qauv hnav. Cov hniav ntse yuav tsis ua rau muaj kev ntuag lossis txiav tsis zoo, uas tuaj yeem ua rau lub tshuab tsis ua haujlwm thiab puas tsuaj.

2. Siv Cov Khoom Siv Zoo

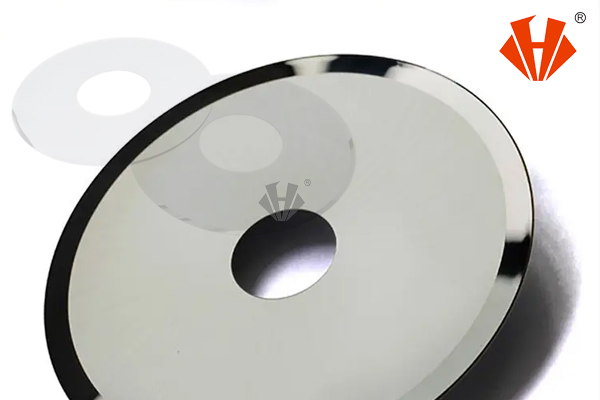

- Xaiv Cov Hniav Zoo:Siv nyiaj rau cov hniav riam uas ua los ntawm cov khoom zoo xws li tungsten carbide lossis high-speed steel. Cov ntaub ntawv no muaj kev tiv thaiv kev hnav, kev tuav ntug, thiab kev ruaj khov zoo heev.

- Cov Hniav Txheej:Xav txog kev siv cov hniav riam uas muaj cov txheej tiv thaiv xeb lossis lwm cov txheej tiv thaiv uas tiv taus kev hnav thiab txo kev sib txhuam.

3. Kev Siv Tshuab Kom Zoo

- Kev Sib Tov Kom Yog:Xyuas kom tseeb tias cov riam tau teeb tsa kom raug hauv lub tshuab. Kev teeb tsa tsis raug tuaj yeem ua rau hnav tsis sib npaug thiab ua rau muaj feem yuav tawg lossis tawg.

- Qhov Chaw Zoo Tshaj Plaws rau Kev Nruj thiab Kev Siab:Kho qhov siab thiab qhov siab ntawm lub tshuab kom haum rau hom ntawv luam yeeb uas koj xav tau. Yog tias koj siv zog ntau dhau, koj yuav ua rau cov riam puas, thiab yog tias koj siv zog tsawg dhau, koj yuav ua rau cov riam tsis sib luag.

4. Tswj Xyuas Kom Huv Si Ua Haujlwm

- Kev Ntxuav Tsis Tu Ncua:Khaws qhov chaw txiav kom huv si thiab tsis muaj hmoov av ntawv, cov khib nyiab, thiab cov khoom seem. Cov khib nyiab uas sib sau ua ke tuaj yeem ua rau cov riam qhuav sai dua thiab cuam tshuam rau lawv txoj kev ua haujlwm.

- Kev siv cov roj lubricants:Siv cov roj nplua nyeem kom tsim nyog rau cov khoom siv ntawm lub tshuab kom txo tau kev sib txhuam thiab kev hnav ntawm cov riam. Xyuas kom tseeb tias cov roj nplua nyeem siv sib xws nrog cov ntaub ntawv ntawm cov hniav thiab tsis ua rau xeb.

5. Kev Siv thiab Khaws Cia Kom Zoo

- Kev Siv Khoom Zoo:Ua tib zoo tuav cov riam thaum lub sijhawm teeb tsa, tshem tawm, lossis hloov pauv kom tsis txhob poob lossis khoov lawv, uas tuaj yeem ua rau tawg lossis puas tsuaj.

- Kev Khaws Cia Kom Muaj Kev Nyab Xeeb:Khaws cov riam seem rau hauv ib qho chaw huv, qhuav, thiab muaj kev nyab xeeb, zoo dua yog muab tso rau hauv cov ntaub thaiv lossis cov thawv kom tsis txhob muaj kev puas tsuaj lossis raug dej noo.

6. Cov Neeg Ua Haujlwm Tsheb Ciav Hlau

- Kev Kawm Txuj Ci rau Cov Neeg Ua Haujlwm:Xyuas kom tseeb tias cov neeg ua haujlwm tshuab tau kawm zoo txog kev siv thiab kev saib xyuas cov riam txiav kom raug. Kev tuav thiab kev siv kom raug yuav txo tau qhov kev puas tsuaj.

7. Saib Xyuas Kev Ua Haujlwm ntawm Lub Tshuab

- Saib Xyuas Kev co thiab Suab Nrov:Kev co lossis suab nrov txawv txawv tuaj yeem qhia txog teeb meem xws li riam tsis sib dhos, tsis muaj zog, lossis teeb meem kho tshuab. Kho cov no sai sai kom tiv thaiv kev puas tsuaj rau riam.

Los ntawm kev siv cov kev tiv thaiv no, koj tuaj yeem ua kom lub neej ntawm cov riam txiav hauv koj lub tshuab ua ntawv luam yeeb ntev dua, ua kom muaj kev ua haujlwm zoo thiab txo cov nqi txij nkawm.

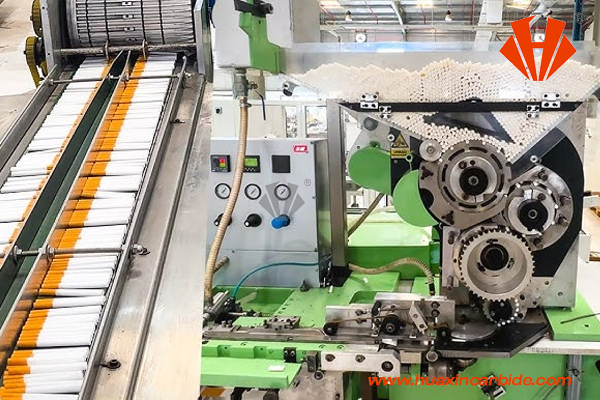

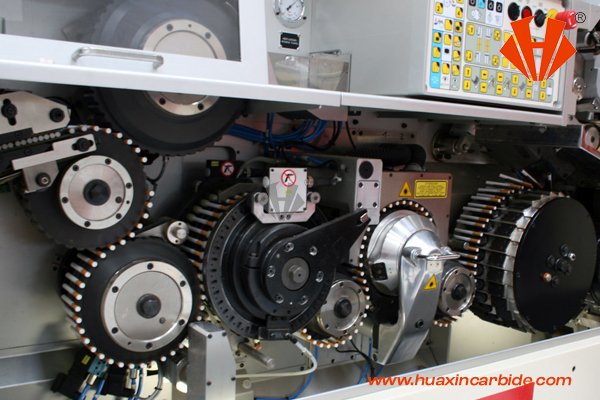

Lub tshuab dov luam yeeb muaj plaub qhov tseem ceeb: kev pub paj rwb, kev tsim, kev txiav thiab kev tswj qhov hnyav, peb cov khoom siv feem ntau yog siv rau hauv qhov txiav. Txhawm rau kom txo lub sijhawm kho thiab txij nkawm kom tsawg kawg nkaus, kev kho qhov chaw iav thiab kev pabcuam txheej tau ua rau peb cov hniav.

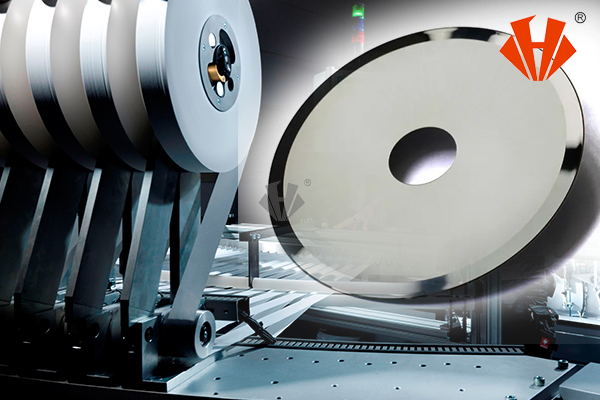

Thaum txiav luam yeeb, yuav tsum txiav kom ntse thiab meej. Vim tias nplooj luam yeeb nyuaj thiab txiav tsis tau. Riam tsis ntse tsuas yog ua rau luam yeeb puas xwb tab sis kuj ua rau txiav tsis sib luag, uas cuam tshuam rau qhov zoo ntawm luam yeeb. Txawm li cas los xij, nrog riam tungsten, cov hniav tseem ntse txawm tias txiav ntau zaus lawm, ua kom luam yeeb raug txiav kom meej thiab yooj yim.

Lwm qhov zoo ntawm kev siv riam tungsten los txiav luam yeeb yog tias nws yooj yim rau kev saib xyuas. Tsis zoo li lwm hom riam, riam tungsten xav tau kev saib xyuas me ntsis. Lawv tsis xeb lossis lwj, thiab lawv tuaj yeem ntxuav tau yooj yim nrog xab npum thiab dej xwb. Qhov no txhais tau tias riam siv tau ntau xyoo yam tsis tas yuav tsum tau ntse lossis hloov, ua rau nws yog qhov kev xaiv pheej yig rau cov neeg txiav luam yeeb.

HUAXIN CEMENTED CARBIDE muab cov riam tungsten carbide zoo tshaj plaws thiab cov hniav rau peb cov neeg siv khoom los ntawm ntau yam lag luam thoob plaws ntiaj teb. Cov hniav tuaj yeem teeb tsa kom haum rau cov tshuab siv hauv txhua daim ntawv thov kev lag luam. Cov ntaub ntawv hniav, ntug ntev thiab cov ntaub ntawv, kev kho mob thiab cov txheej txheem tuaj yeem hloov kho rau kev siv nrog ntau cov ntaub ntawv kev lag luam

Lub sijhawm tshaj tawm: Lub Kaum Hli-12-2024