Cov Hniav Txiav Tshuaj Fiber lossis Cov Hniav Txiav Staple Fiber

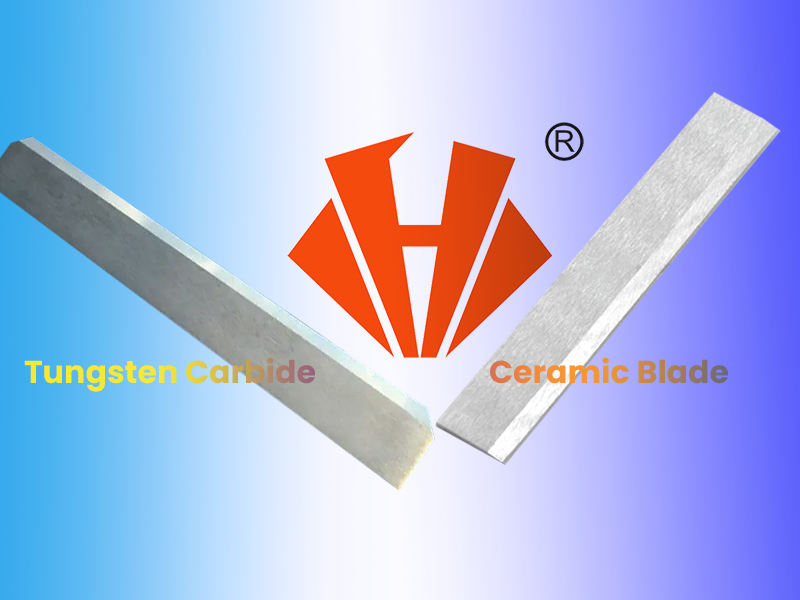

SCov hniav olid Tungsten Carbide (STC) thiab cov hniav Solid Ceramic yog ob qho tib si cov cuab yeej txiav ua haujlwm siab, tab sis lawv muaj cov yam ntxwv thiab kev siv sib txawv vim qhov sib txawv ntawm lawv cov ntaub ntawv. Nov yog kev sib piv ntawm lawv cov kev siv raws li qhov sib txawv tseem ceeb:

1. Cov Khoom Siv thiab Cov Khoom

Khoom khov khoTungsten Carbide Hniav

- Kev sau ua keUa los ntawm tungsten carbide, uas yog kev sib xyaw ua ke ntawm tungsten thiab carbon, feem ntau sib txuas nrog cobalt.

- Qhov nyuaj: Nyuaj heev (ze li pob zeb diamond ntawm qhov nyuaj), tab sis tsis yooj yim tawg dua li cov khoom ua los ntawm av nplaum.

- Kev tawv ncauj: Muaj kev tawv zoo heev, txhais tau tias nws tuaj yeem tswj tau qhov cuam tshuam thiab kev txiav siab zoo dua li cov khoom siv ceramics.

- Kev Tiv Thaiv Hnav: Kev tiv taus kev hnav siab heev, tsim nyog rau kev siv mus sij hawm ntev hauv kev teeb tsa kev lag luam.

Cov Hniav Ceramic Khoom

- Kev sau ua keFeem ntau yog ua los ntawm cov ntaub ntawv xws li zirconia lossis silicon carbide.

- Qhov nyuaj: Txawm tias nyuaj dua li tungsten carbide, tab sis nws kuj yooj yim tawg.

- Kev tawv ncauj: Tsis tshua muaj zog piv rau carbide, ua rau nws yooj yim tawg lossis tawg thaum muaj kev cuam tshuam.

- Kev Tiv Thaiv Hnav: Kuj tseem hnav tau zoo heev tab sis tuaj yeem hnav tsis sib npaug thaum siv rau ntawm cov ntaub mos dua.

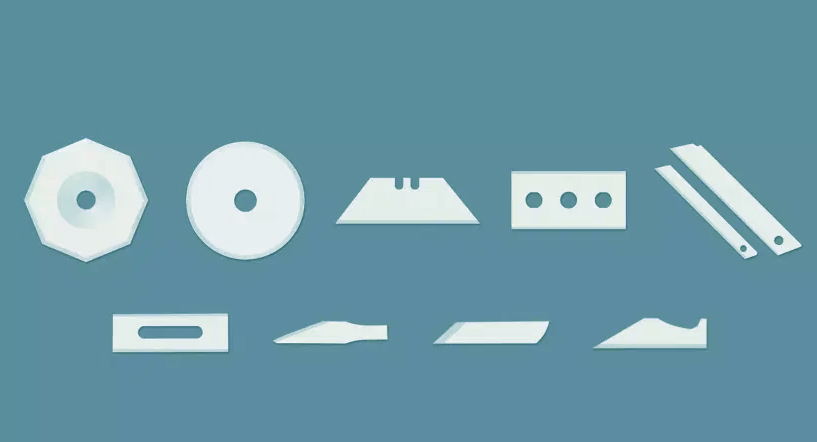

2. Cov ntawv thov

Cov Hniav Tungsten Carbide Khoom:

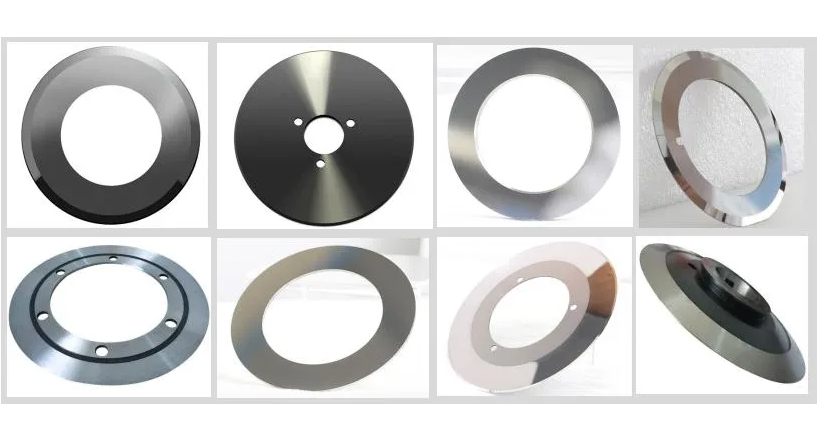

- Kev Txiav Hlau thiab Kev Sib Xyaws: Nyiam siv rau hauv cov ntawv thov hnyav xws li txiav lossis tshuab cov hlau, cov khoom sib xyaw, thiab lwm yam khoom tawv.

- Kev Txiav Txim SiabSiv rau hauv cov ntawv thov uas xav tau kev sib npaug ntawm qhov ntse thiab kev ruaj khov, xws li kev txiav hauv kev lag luam (piv txwv li, cov ntawv ci hlau, cov yeeb yaj kiab, thiab ntawv).

- Kev Ua Haujlwm Siab SiabZoo tagnrho rau kev ua haujlwm uas muaj kev txiav siab, xws li kev khawb, kev sib tsoo, thiab kev sib tsoo hauv kev lag luam xws li tsheb, aerospace, thiab kev tsim khoom.

- Lub Neej Ntev Dua Hauv Cov Xwm Txheej Cuam Tshuam: Haum rau cov tshuab uas cov hniav yuav raug kev cuam tshuam lossis kev co vim nws lub zog.

Cov Hniav Ceramic Khoom:

- Kev Txiav Txim Siab Ntawm Cov Khoom Mos MosSiv rau hauv cov ntawv thov precision xws li txiav zaj duab xis, fiber optics, plastics, thiab textiles. Qhov nyuaj heev muab qhov ntse tshwj xeeb tab sis feem ntau tsuas yog siv rau cov ntaub ntawv uas tsis tshua muaj abrasive.

- Kev Ua Haujlwm Kub SiabZoo tagnrho rau cov chaw uas kub heev tuaj yeem cuam tshuam rau cov cuab yeej txiav, vim tias cov khoom siv ceramic tuaj yeem tswj lawv cov khoom hauv qhov kub heev.

- Kev Tiv Thaiv Kev XebFeem ntau xaiv rau hauv cov chaw uas muaj tshuaj lom neeg lossis dej noo yuav ua rau cov hniav hlau lwj, xws li hauv kev ua zaub mov, kev siv kho mob, thiab kev lag luam tshuaj lom neeg.

- Cov Ntawv Thov ZooSiv rau hauv cov xwm txheej uas cov khoom siv yooj yim puas, thiab cov hniav yuav tsum muab cov txiav zoo heev, huv si (piv txwv li, hauv cov khoom siv hluav taws xob, kev tsim khoom semiconductor).

3. Kev Xav Txog Kev Ua Tau Zoo

Cov Hniav Tungsten Carbide Khoom:

- Zoo dua rau cov ntawv thov txiav kev ntxhov siab vim nws lub zog.

- Yuav rov ua kom ntse dua ntau zaus, ua kom nws lub neej ntev dua.

- Kev kam rau siab dua rau cov ntaub ntawv abrasive xws li hlau thiab cov khoom sib xyaw ntom ntom.

Cov Hniav Ceramic Khoom:

- Zoo tagnrho thaum qhov chaw txiav xav tau tsawg kawg nkaus reactivity nrog cov khoom raug txiav (piv txwv li, cov hniav kho mob).

- Tsis kam rau kev cuam tshuam, yog li lawv siv rau hauv cov xwm txheej qis-kev co, siab-precision.

- Feem ntau, tsis tuaj yeem rov ua kom ntse dua yooj yim, ua rau lawv yog ib qho kev xaiv pov tseg ntau dua hauv qee kis.

- Tungsten Carbide Hniavraug nyiam siv rau hauv kev siv hauv kev lag luam uas qhov kev tawv, kev ruaj khov, thiab kev tiv thaiv kev hnav thaum muaj kev nyuaj siab yog qhov tseem ceeb, tshwj xeeb tshaj yog nrog cov ntaub ntawv nyuaj dua lossis ntau dua abrasive.

- Cov Hniav Ua Los Ntawm Cov Khoom Siv Ceramicua tau zoo hauv qhov raug, tsis muaj kev cuam tshuam, thiab qhov kub siab, txiav cov khoom mos dua thiab hauv cov xwm txheej uas kev tiv thaiv tshuaj lom neeg yog qhov tseem ceeb. Lawv tsis haum rau cov xwm txheej muaj kev cuam tshuam siab lossis kev ntxhov siab vim lawv qhov tsis yooj yim tawg.

Cov kev sib txawv no coj kev xaiv ntawm txhua hom hniav nyob ntawm seb cov kev xav tau tshwj xeeb ntawm cov txheej txheem txiav.

HUAXIN CEMENTED CARBIDE muab cov riam tungsten carbide zoo tshaj plaws thiab cov hniav rau peb cov neeg siv khoom los ntawm ntau yam lag luam thoob plaws ntiaj teb. Cov hniav tuaj yeem teeb tsa kom haum rau cov tshuab siv hauv txhua daim ntawv thov kev lag luam. Cov ntaub ntawv hniav, ntug ntev thiab cov ntaub ntawv, kev kho mob thiab cov txheej txheem tuaj yeem hloov kho rau kev siv nrog ntau cov ntaub ntawv kev lag luam

Lub sijhawm tshaj tawm: Lub Kaum Hli-29-2024