Hauv ntiaj teb kev txiav hauv kev lag luam, kev ua kom raug thiab kev ruaj khov yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo. Thaum nws los txog rau kev txiav cov zaj duab xis nyias hauv kev lag luam xws li kev ntim khoom, khoom siv hluav taws xob, thiab ntaub, kev siv hom hniav zoo tuaj yeem ua qhov sib txawv tseem ceeb hauv kev ua haujlwm zoo thiab qhov zoo ntawm cov khoom. Ib qho kev daws teeb meem zoo li no uas tau nce ntxiv yograb riam txiav 3-qhov, ib lub cuab yeej tshwj xeeb uas tsim los muab kev ua tau zoo tshaj plaws hauv kev txiav thiab txiav cov yeeb yaj kiab.

Cov Riam Phom 3-Qhov yog dab tsi?

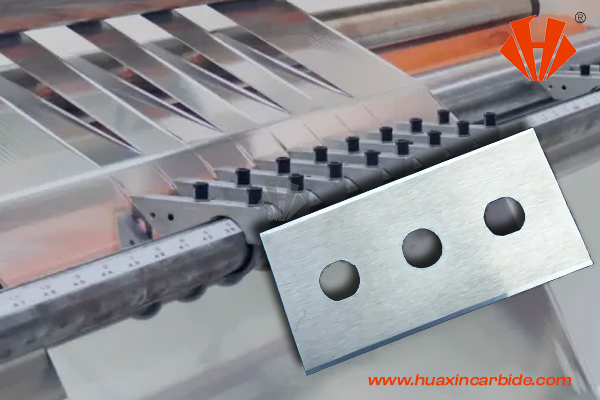

Kuj tseem hu uaCov hniav riam 3-qhov rau kev lag luam, cov cuab yeej txiav no muaj peb lub qhov uas tau teeb tsa raws qhov chaw ntawm lawv qhov chaw. Cov qhov no ua lub luag haujlwm tseem ceeb hauv kev txhim kho kev ua haujlwm thiab kev ua haujlwm ntawm cov hniav thaum lub sijhawm txiav. Thaum lawv qee zaum raug xa mus raucov hniav slotted or cov hniav riam nrog peb lub qhov, tus qauv tsim thiab cov khoom siv ntawm cov hniav no tso cai rau lawv los daws cov haujlwm txiav siab tau yooj yim.

Cov txiaj ntsig tseem ceeb ntawm 3-Qhov Razor Blades rau Kev Txiav Zaj Duab Xis

- Kev Ua Kom Zoo Dua Hauv Kev Txiav

Ib qho ntawm cov txiaj ntsig zoo tshaj plaws ntawmpeb lub qhov riam txiavyog lawv lub peev xwm los tswj qhov zoo ntawm kev txiav. Peb lub qhov tau muab tso rau hauv qhov chaw zoo kom txo qhov kev pheej hmoo ntawm cov hniav tsis sib xws thaum lub sijhawm ua haujlwm. Qhov no ua rau muaj kev txiav raug dua thiab cov npoo huv dua, uas yog qhov tseem ceeb tshwj xeeb thaum ua haujlwm nrog cov ntaub ntawv mos xws li zaj duab xis nyias. Txawm hais tias daim ntawv thov yog rau kev txiav cov yas zaj duab xis, cov ntaub ntawv ntim khoom yooj ywm, lossis lwm yam khoom nyias nyias, qhov ntse thiab qhov tseeb ntawm 3-qhov hniav riam ua kom muaj kev pov tseg tsawg kawg nkaus thiab qib siab dua ntawm cov khoom tiav.

- Kev Ua Tau Ntev thiab Kev Siv Tau Ntev Dua

Hauv cov chaw ua haujlwm, cov hniav yuav tsum muaj peev xwm tiv taus kev hnav thiab tsim kua muag, tshwj xeeb tshaj yog thaum txiav los ntawm cov ntaub ntawv tawv xws li cov yeeb yaj kiab lossis cov ntaub ntawv sib xyaw.Peb lub qhov riam txiav riamtau tsim los nrog kev ruaj khov hauv siab. Qhov kev teeb tsa peb lub qhov pab faib cov zog txiav kom sib npaug ntau dua thoob plaws ntawm qhov chaw ntawm cov hniav, ua rau kev hnav tsawg dua thiab kev ua haujlwm ntev dua. Qhov no tsis yog tsuas yog ua rau lub neej ntawm cov hniav ntev dua xwb tab sis kuj txo qhov zaus ntawm kev hloov cov hniav, thaum kawg txuag cov lag luam lub sijhawm thiab nyiaj txiag.

- Kev Ruaj Ntseg Zoo Dua Thaum Lub Sijhawm Ua Haujlwm

Qhov kev tsim peb lub qhov kuj tseem ua rau kom lub hniav ruaj khov thaum lub sijhawm ua haujlwm. Thaum muab tso rau hauv lub tshuab txiav lossis lwm yam khoom siv txiav kev lag luam, cov hniav no raug tuav kom ruaj khov dua, txo qhov muaj feem ntawm cov hniav co lossis txav uas yuav cuam tshuam rau qhov zoo ntawm kev txiav. Qhov kev ruaj khov no yog qhov tseem ceeb hauv cov txheej txheem txiav ceev ceev, qhov twg txawm tias qhov me me tsis sib xws tuaj yeem ua rau muaj qhov tsis zoo hauv zaj duab xis thiab txo qis kev ua haujlwm.

- Cov Khoom Siv Zoo Tshaj Plaws Rau Kev Txiav Ua Haujlwm Zoo

Cov tuam txhab zoo liHuxin Cemented Carbide(www.huaxincarbide.com)tsom mus rau kev tsim cov khoom siv siab heevcov hniav carbide nyias zaj duab xisLos ntawm kev siv cov ntaub ntawv ua tau zoo xws li cemented carbide, Huxin ua kom ntseeg tau tias lawv cov hniav riam tsis yog tsuas yog muab qhov ntse tshaj plaws xwb tab sis kuj tseem muaj qhov nyuaj thiab hnav tsis kam. Cemented carbide yog paub zoo txog nws lub peev xwm los tiv taus cov xwm txheej hnyav, ua rau nws yog cov khoom siv zoo tshaj plaws rau cov hniav siv hauv kev txiav kev lag luam uas lub neej ntev thiab qhov tseeb yog qhov tseem ceeb.

- Txo Kev Sib Txhuam thiab Kev Tsim Kub

Lwm qhov zoo tseem ceeb ntawmrab chais nrog peb lub qhovyog qhov txo qhov kev sib txhuam ntawm cov hniav thiab cov khoom siv uas raug txiav. Tus qauv tsim peb lub qhov pab kom cov cua sov tawm zoo dua, tiv thaiv cov hniav kom tsis txhob kub dhau thiab ua haujlwm tsis zoo dhau sijhawm. Qhov no tseem ceeb heev thaum txiav cov yeeb yaj kiab, vim tias cov cua sov ntau dhau tuaj yeem ua rau cov khoom puas, ua rau cov khoom kawg tsis zoo. Los ntawm kev tswj qhov chaw txiav txias dua, cov hniav no tuaj yeem ua tiav kev txiav du thiab ntev lub neej ntawm cov hniav.

- Kev Siv Tau Ntau Yam Hauv Ntau Yam Kev Txiav

Peb lub qhov riam txiav riammuaj ntau yam siv tau thiab siv tau thoob plaws ntau yam lag luam uas xav tau kev txiav cov zaj duab xis nyias thiab lwm yam khoom siv kom raug. Lawv zoo tagnrho rau kev siv hauv cov tshuab txiav zaj duab xis, cov kab ntau lawm ntim khoom, thiab ntau yam kev siv hauv kev lag luam uas xav tau kev txiav zoo. Qhov sib xws hauv kev tsim qauv ua kom ntseeg tau tias cov hniav ua haujlwm tas li ntawm ntau yam khoom siv, txawm tias nws yog zaj duab xis yas, cov ntawv ci hlau, lossis cov khoom ua los ntawm ntawv.

- Txo qhov sib tham thiab kev co ntawm cov hniav

Cov qhov hauv cov hniav kuj ua lub luag haujlwm hauv kev txo cov suab nrov thiab kev co thaum lub sijhawm txiav. Qhov no yog qhov tshwj xeeb tshaj yog thaum txiav ntawm qhov ceev ceev, qhov twg qhov tsis ruaj khov ntawm cov hniav tuaj yeem ua rau cov txiav tsis zoo thiab hnav ntau dua.cov hniav riam 3-qhov rau kev lag luamtau tsim los txo cov teeb meem no, ua rau kev ua haujlwm du thiab zoo dua yav tom ntej.

Lubpeb lub qhov riam txiavsawv cev rau kev nce qib hauv kev siv tshuab hauv kev txiav kev lag luam, tshwj xeeb tshaj yog rau cov ntawv thov zaj duab xis nyias. Lawv tus qauv tsim muaj ntau yam zoo, los ntawm kev ua kom raug thiab ruaj khov mus rau kev ruaj khov thiab kev ua tau zoo dua. Los ntawm kev xaiv cov hniav zoo ua los ntawm cov khoom siv siab heev xws li cemented carbide, cov tuam txhab tuaj yeem ua tiav cov txiaj ntsig zoo dua thaum txo cov nqi kho thiab lub sijhawm tsis ua haujlwm.Huxin Cemented Carbideua piv txwv txog lub peev xwm ntawm cov thev naus laus zis carbide, tsim cov hniav uas zoo tshaj plaws hauv qhov nyuaj, tiv taus kev hnav, thiab ntse, ua rau lawv yog tus khub ntseeg siab rau cov lag luam uas xav tau cov cuab yeej txiav txhim khu kev qha thiab ua tau zoo.

Rau cov lag luam uas koom nrog kev txiav thiab txiav zaj duab xis, kev nqis peev rau hauvcov hniav riam nrog peb lub qhovyog ib qho kev xaiv ntse uas tuaj yeem ua rau muaj kev ua haujlwm zoo dua, txo cov nqi ua haujlwm, thiab, qhov tseem ceeb tshaj plaws, cov khoom tiav zoo dua.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-18-2024