Hauv cov txheej txheem tsim cov cuab yeej txiav carbide rau kev txiav cov tshuaj fiber (siv rau kev txiav cov ntaub ntawv xws li nylon, polyester, thiab carbon fiber), cov txheej txheem no nyuaj heev, suav nrog ntau kauj ruam tseem ceeb suav nrog kev xaiv cov ntaub ntawv, kev tsim, sintering, thiab kev ua ntug. Txhua kauj ruam yuav muaj cov teeb meem kev siv tshuab. Hauv qab no yog cov teeb meem tseem ceeb uas ntsib thaum lub sijhawm tsim khoom thiab lawv cov kev daws teeb meem.

I. Cov Teeb Meem Hauv Theem Npaj Khoom Siv

1. Tsis Txaus Homogeneity ntawm WC-Co Hmoov

Tej zaum qhov teeb meem yog:

Kev sib xyaw tsis sib xws ntawm cov hmoov cemented carbide (WC-Co) ua rau muaj kev sib cais ntawm cov khoom sib xyaw tom qab sintering, ua rau muaj kev sib npaug ntawm qhov nyuaj thiab tawv.

Cov kev daws teeb meem rau koj:

Ua kom cov hmoov sib xws zoo dua los ntawm kev sib tsoo pob zog siab lossis ziab tshuaj tsuag.

Ntxiv cov tshuaj tiv thaiv kev loj hlob ntawm cov noob (piv txwv li, Cr₃C₂, VC) los tswj qhov loj ntawm cov noob WC (0.5–1 μm).

2. Kev Faib Tawm Tsis Sib Npaug ntawm Theem Binder (Co)

Tej zaum qhov teeb meem yog:

Kev sib sau ua ke ntawm cov theem sib koom ua ke tsim cov "cobalt pools," txo qhov kev tiv thaiv kev cuam tshuam thiab ua rau ntug chipping thaum txiav fiber.

Peb ua tau dab tsi:

Siv cov hmoov nano-cobalt (<100 nm) nrog kev sib tsoo ntub kom txhim kho kev sib kis.

Kho qhov kub ntawm kev sintering (tswj 1400–1450 ° C thaum lub sijhawm sintering ua kua).

II. Cov Teeb Meem ntawm Kev Tsim thiab Sintering

1. Qhov Tsis Zoo Hauv Kev Tsim Tshuab Nias

Tej zaum qhov teeb meem yog:

Qhov tsis sib xws ntawm qhov ceev thaum lub sijhawm nias txias isostatic (CIP) lossis nias tuag ua rau muaj kab nrib pleb / delamination hauv cov cev ntsuab.

Cov kev daws teeb meem rau koj:

Ua kom zoo dua qhov siab nias (200–300 MPa) thiab lub sijhawm nyob.

Txais yuav kev nias ob txoj kev lossis kev txhaj tshuaj hlau (MIM) rau cov qauv geometries nyuaj.

2. Kev Hloov Pauv Sintering thiab Kev Tsis Txawj Ntse ntawm Qhov Ntev

Tej zaum qhov teeb meem yog:

Qhov tsis ruaj khov ntawm sintering shrinkage (feem ntau yog 15–20%) ua rau muaj kev hloov pauv ntawm ntug geometry ntau dhau (piv txwv li, ntug radius >10 μm).

Cov Kev Tswj:

Siv cov pwm graphite + Al₂O₃ spacers kom txo qhov kev hloov pauv kub siab.

Siv cov spark plasma sintering (SPS) los txo lub sijhawm sintering thiab porosity (<0.5%).

III. Kev Sib Tw ntawm Kev Ua Ntug thiab Kev Txheej Txheem

1. Kev Sib Tsoo Ntug Uas Muaj Kev Ntsuas Zoo Tshaj Plaws

Tej zaum qhov teeb meem yog:

Kev ua tiav cov npoo ntse (ntug vojvoog <5 μm) raug cuam tshuam los ntawm qhov nyuaj siab (HRA ≥90), ua rau kev sib tsoo tsis zoo thiab lub log hnav sai.

Kev Txhim Kho Cov Txheej Txheem:

Siv cov log pob zeb diamond (qhov loj ntawm cov xuab zeb W10–W20) nrog rau kev hnav khaub ncaws electrolytic in-process (ELID).

Txais yuav laser-assisted grinding (LAG) los txo qhov sib tsoo zog thiab txhim kho qhov roughness ntawm qhov chaw (Ra ≤0.1 μm).

2. Kev nplaum tsis txaus ntawm txheej txheej

Tej zaum qhov teeb meem yog:

Cov txheej txheej TiAlN/DLC tev tawm thaum lub sijhawm txiav ceev ceev ntawm cov fibers hluavtaws (tshwj xeeb tshaj yog cov fibers carbon uas ua los ntawm cov resin).

Cov Tswv Yim Txhim Kho:

Kev kho ua ntej: Kev ntxuav Ar⁺ ion bombardment + Cr interlayer (tuab 0.2–0.5 μm).

Hloov mus rau ntau txheej txheej gradient (piv txwv li, TiCN/AlTiO₃), txhim kho kev nplaum los ntawm >30%.

Txog Huaxin: Tungsten Carbide Cemented Slitting Riam Chaw Tsim Khoom

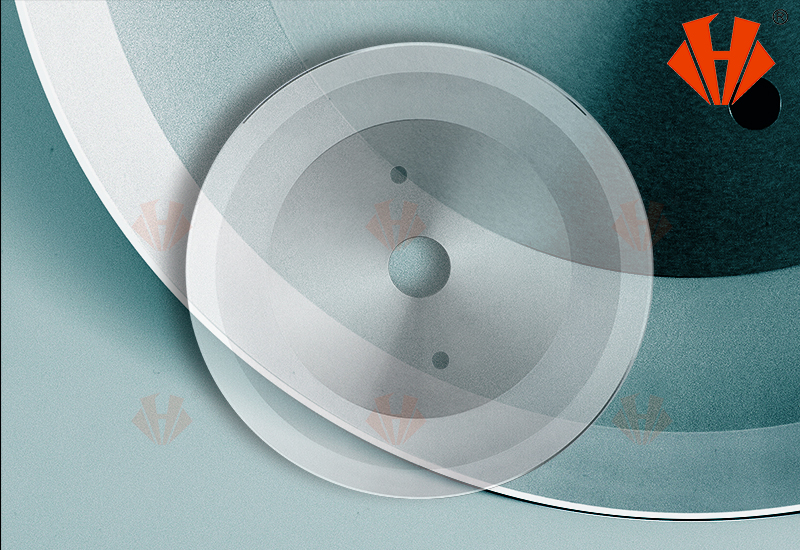

CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD yog cov kws tshaj lij thiab cov chaw tsim khoom ntawm cov khoom tungsten carbide, xws li cov riam ntxig carbide rau kev ua haujlwm ntoo, cov riam puag ncig carbide rau kev txiav cov pas nrig luam yeeb & luam yeeb, cov riam puag ncig rau kev txiav corugatted cardboard, peb lub qhov riam txiav / cov hniav slotted rau kev ntim khoom, daim kab xev, txiav zaj duab xis nyias, cov hniav txiav fiber rau kev lag luam textile thiab lwm yam.

Nrog ntau tshaj 25 xyoo kev txhim kho, peb cov khoom tau raug xa tawm mus rau Tebchaws Meskas A, Russia, South America, Is Nrias teb, Qaib ntxhw, Pakistan, Australia, Southeast Asia thiab lwm yam. Nrog rau qhov zoo heev thiab cov nqi sib tw, Peb tus cwj pwm ua haujlwm hnyav thiab kev teb tau txais kev pom zoo los ntawm peb cov neeg siv khoom. Thiab peb xav tsim kom muaj kev sib raug zoo ua lag luam tshiab nrog cov neeg siv khoom tshiab.

Tiv tauj peb hnub no thiab koj yuav txaus siab rau cov txiaj ntsig zoo thiab cov kev pabcuam los ntawm peb cov khoom!

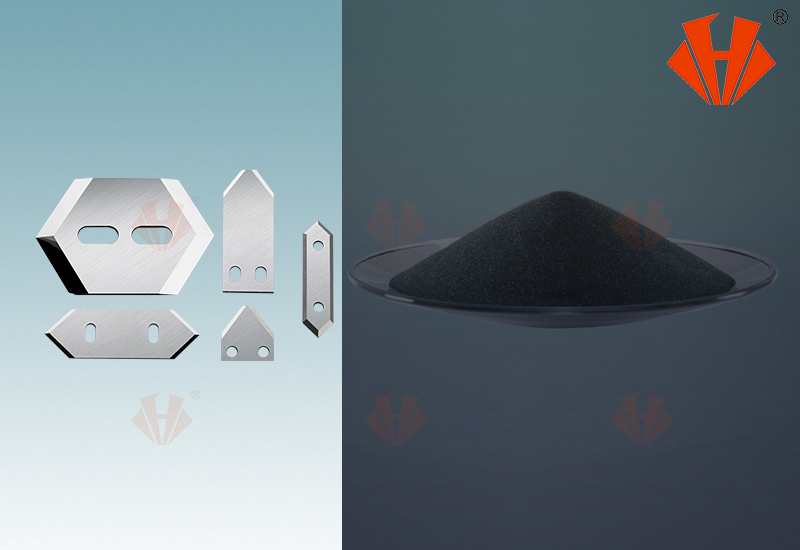

Cov khoom siv tungsten carbide industrial blades ua tau zoo heev

Kev Pabcuam Tshwj Xeeb

Huaxin Cemented Carbide tsim cov hniav tungsten carbide, hloov kho tus qauv thiab tus qauv blanks thiab preforms, pib los ntawm hmoov mus txog rau hauv av tiav. Peb cov kev xaiv ntawm cov qib thiab peb cov txheej txheem tsim khoom ib txwm muab cov cuab yeej ua haujlwm siab, txhim khu kev qha ze-net uas daws cov teeb meem tshwj xeeb ntawm cov neeg siv khoom thoob plaws ntau yam lag luam.

Cov Kev Daws Teeb Meem Rau Txhua Lub Lag Luam

cov hniav uas tsim tshwj xeeb

Cov chaw tsim khoom ua lag luam ntawm cov hniav riam

Cov lus nug uas cov neeg siv khoom feem ntau nug thiab cov lus teb ntawm Huaxin

Qhov ntawd nyob ntawm seb muaj pes tsawg, feem ntau yog 5-14 hnub. Ua ib lub chaw tsim khoom siv riam, Huaxin Cement Carbide npaj cov khoom tsim los ntawm kev txiav txim thiab cov neeg siv khoom thov.

Feem ntau yog 3-6 lub lis piam, yog tias koj thov cov riam tshuab lossis cov hniav ua haujlwm uas tsis muaj nyob hauv Tshuag thaum lub sijhawm yuav khoom. Nrhiav Sollex Kev Yuav Khoom & Kev Xa Khoom ntawm no.

yog tias koj thov cov riam tshuab lossis cov hniav ua haujlwm uas tsis muaj nyob hauv Tshuag thaum lub sijhawm yuav khoom. Nrhiav Sollex Cov Cai Yuav Khoom & Kev Xa Khoom.nyob ntawm no.

Feem ntau T/T, Western Union...tso nyiaj ua ntej, Txhua qhov kev txiav txim thawj zaug los ntawm cov neeg siv khoom tshiab yog them ua ntej. Cov kev txiav txim ntxiv tuaj yeem them los ntawm daim ntawv qhia nqe...tiv tauj pebkom paub ntau ntxiv

Yog, tiv tauj peb, Cov riam ua lag luam muaj ntau hom, suav nrog cov riam puag ncig sab saud, cov riam puag ncig hauv qab, cov riam serrated / hniav, cov riam perforating puag ncig, cov riam ncaj, cov riam guillotine, cov riam taw tes, cov hniav rab chais plaub fab, thiab cov hniav trapezoidal.

Yuav kom pab tau koj tau txais cov hniav zoo tshaj plaws, Huaxin Cement Carbide yuav muab ntau cov hniav piv txwv rau koj los sim hauv kev tsim khoom. Rau kev txiav thiab hloov cov ntaub ntawv yooj ywm xws li zaj duab xis yas, ntawv ci, vinyl, ntawv, thiab lwm yam, peb muab cov hniav hloov pauv suav nrog cov hniav slitter thiab cov hniav razor nrog peb qhov. Xa peb cov lus nug yog tias koj xav tau cov hniav tshuab, thiab peb yuav muab rau koj nrog kev thov. Cov qauv rau cov riam ua kev cai tsis muaj tab sis koj tuaj yeem txais tos kom xaj qhov tsawg kawg nkaus.

Muaj ntau txoj hauv kev uas yuav ua rau koj cov riam thiab cov hniav ua haujlwm ntev dua thiab siv tau ntev dua. Tiv tauj peb kom paub txog kev ntim khoom zoo ntawm cov riam hauv tshuab, cov xwm txheej khaws cia, av noo thiab huab cua kub, thiab cov txheej ntxiv yuav tiv thaiv koj cov riam thiab tswj lawv cov kev ua haujlwm txiav.

Lub sijhawm tshaj tawm: Lub Yim Hli-15-2025